In a fertilizer granules production line, granulating is a key process. Whether you want to make compound fertilizer granules or turn your composted organic fertilizers powder into granules, you should equip with a fertilizer granulator. With a granulation machine, you can turn powdery materials into granules easily and efficiently. As a professional fertilizer granulator manufacturer, there are many kinds of granulation machines for you to choose. Each of them have their own characters. They use different granulation technologies for turning powder into granules. Meanwhile, for your different materials, we will recommend different granulation machines for you.

For example, for your organic animal manure fertilizer making, our pan granulator, new designed fertilizer granulation machine and the rotary drum stirring granulator are applicable. While, if you want to buy a granulator for your compound dry powder granulation line, the double roller granulation equipment is the most suitable machine. Meanwhile, our company manufactures many specifications of fertilizer granulators for your different requirements on the production capacities.

NPK Compound Fertilizer Granulation Equipment

Rotary Gear Drum Granulator

Rotary Drum Granulator

Pan Granulator

New Type Organic Fertilizer Granulator

New Design Bio Pellet Machine

Double Roller Granulator

Disc Granulator

What kind of raw materials can Shunxin fertilizer granulator process?

Shunxin fertilizer granule machine can work with different kinds of organic materials. It is especially suitable for granulation of light-weight, highly sticky and fine powders. The finer powders you use, the higher quality and rounder fertilizer pellet products you get. The specific materials include livestock and poultry manure, compost, green manure, sea manure, cake fertilizer, turf, mixed soil fertilizer, municipal waste, sludge, microbes, humus, herb residues, crops straws, slag, dregs, etc. Accordingly, there are also different manure fertilizer pellet machine for you to choose. You can use for for organic poultry manure pelletizing, chicken manure granulating, cow dung fertilizer granules making and so on.

Most of these materials are wastes and residues, they are easy to get, with cheap prices and huge quantities. You can easily use Shunxin fertilizer granules making machine to process them into valuable organic fertilizer pellets. Especially, using Shunxin fertilizer granulation machine to produce animal manure fertilizer granules, the fertilizer granulation effects will be better than other materials. Meanwhile, for your different manure processing requirements, Shunxin provides you different granulators for your reference. You can choose a suitable one according to your production capacity, budget and preference.

Poultry Manure Pellet Machine

Horse Manure Pellet Maker

Earthworm Fertilizer Granulator

Cow Manure Fertilizer Pellet Machine

Chicken Manure Pellet Machine

Hot sale granulator recommendation for fertilizers granules making

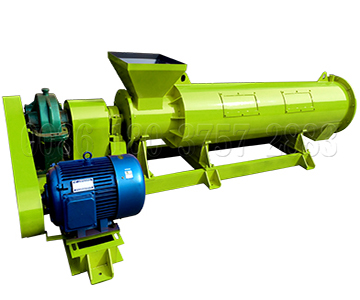

For your fertilizer making plant, Shunxin provides you both compound and organic fertilizer granulation machines for your granular fertilizer making. Here we recommend you two types of popular fertilizer granulators for your organic and compound fertilizer granulation line respectively. For your organic fertilizer granules making, the new patent organic fertilizer granulator is the most suitable machine. And for making high quality compound fertilizers pellets, our fertilizer roller compactor will be a good choice.

New designed organic manure fertilizer granules making machine for sale

Generally, the new fertilizer granulator is a kind of shaping machine. It can process raw materials into round ball-like fertilizer pellets. Shunxin patent fertilizer pelletizer only consumes relative low energy, but it can mass produce organic fertilizers with high pelletizing ratio. So, it can help you a lot in your fertilizer granulation plants. What’s more, this fertilizer dedicated granulator is also called the stirring teeth granulator. Because it works with a number of sharp and durable teeth to mix the raw materials.

As a result, it can deal with coarse fiber materials that other types of fertilizer granulators may find difficult to process, like crop straws, slag, dregs, etc. For your information, combining with other Shunxin fertilizer equipment, you can get a fertilizer production line with higher efficiency. The best equipment configurations are compost making machine, fertilizer crusher, mixer, screenner, drum dryer, cooler, polishing machine, conveyor, etc.

|

Model |

Installation Angle |

Capacity(t/h) |

Power(kw) |

Feed Moisture |

Feed Size(mesh) |

Overall Size(mm) |

|

SXJZ – 600 |

2°-2.5° | 1 – 1.5 | 37 | 20% – 40% | 50 |

4100 x 1600 x 1150 |

|

SXJZ – 800 |

2°-2.5° | 1.5 – 2.5 | 55 | 20% – 40% | 50 |

4250 x 1850 x 1300 |

|

SXJZ – 1000 |

2°-2.5° | 2 – 4 | 75 | 20% – 40% | 50 |

4700 x 2350 x 1600 |

|

SXJZ – 1200 |

2°-2.5° | 4 – 6 | 90 | 20% – 40% | 50 |

4900 x 2550 x 1800 |

|

SXJZ – 1500 |

2°-2.5° | 6 – 8 | 110 | 20% – 40% | 50 |

5500 x 2800 x 2000 |

Dry extrusion double roller granulator for compound dry powder granulation

For your dry compound fertilizer powder granulation, this fertilizer roller compactor is suitable for you. It can process the dry powder, whose moisture content is about 5% to 10%. And different from the pan, drum and stirring type organic fertilizer granulator, the double roller granulation machine utilizes extrusion force for pelletizing. It can pelletize your compound dry powder into oval granules. Meanwhile, using this granualtor for pelletizing compound fertilizers, you do not need to equip with a drying or cooling machine. The granulated fertilizer granules are suitable for packing directly.

|

Model |

Power(kw) |

Pellets Diameter (mm) |

Roller Sheet Size(mm) |

Overall Size(mm) |

|

SXJZ – 1T |

Pellet Diameter ≦4.5mm : 11

Pellet Diameter >4.5mm: 15 |

3 – 10 | Φ 150 x 220 |

1450 * 800 * 1450 |

|

SXJZ – 1.5T |

Pellet Diameter ≦4.5mm : 18.5

Pellet Diameter >4.5mm: 22 |

3 – 10 | Φ 150 x 300 |

1450 * 850 * 1500 |

|

SXJZ – 2T |

Pellet Diameter ≦4.5mm : 22

Pellet Diameter >4.5mm: 30 |

3 – 10 | Φ 185 x 300 |

1630 * 850 * 1650 |

How Many Procedures you should do when you use Shunxin fertilizer granulator?

Using fertilizer granulation machines for making fertilizer granules, there are some tips for you to know them better. Here you can know the preparations, working principle of the granulating. Meanwhile, if you want to control the size of fertilizer granules, we also have operating methods for your reference.

Preparation

Shunxin fertilizer pellet making machine adopts wet granulation to work, so you need to make sure the moisture of the raw materials is between 20% – 40% after fermentation. You can prepare the materials by using Shunxin high quality dewatering machine, compost making machine( or fermentation pot ) and fertilizer crusher machine.

The dewatering machine can lower the moisture content of fresh organic manure waste. Doing this, the compost process will be more efficient. Meanwhile, for quickening the composting process, the organic manure compost making machine will help you finish the whole composting process in only 20 days. After the composting, you can get available organic manure compost fertilizers. For your fertilizer granules making requirements, you had better make the composted organic fertilizer powder finer. A compost fertilizer crushing equipment will be helpful.

Composted fertilizer powder granulating

Start the machine, then put the materials in via inlet atop. The materials will meet the rotating teeth which attached on the rotor, and be further shredded. As the rotor keeps spinning, the teeth will stir the materials, mix them up. With the high speed rotating, there comes the powerful centrifugal force.

Meanwhile, the sizes of the pellets are controllable. If you use raw materials which contain much water, and lower the speed of the rotor, then you can get larger size fertilizer granules. If you lower the moisture of the materials and raise the speed of the rotor, you will get smaller pellets. You can test it in the trial production to decide the water content rate. During production, you should keep the consistency of the feed speed and the moisture content rate, so that you can get uniformly granulated pellets.

Granulated organic manure fertilizer processing

Combined with the stirring teeth, they will condense and sphere the material particles, make them into round fertilizer pellets. When the granules grow large enough in size, they will leave the machine through the outlets automatically. If you equip with a Shunxin fertilizer screener, you can further sort the pellets. Moreover, because the organic manure granulation machines are wet granulator, the pelleted organic animal manure fertilizers are wet. You can equip with a drying and cooling equipment before screening for lowering the moisture content and temperature of organic fertilizers granules. Finally, there is packing machine for you to pack the finished organic fertilizer products efficiently and accurately.

How to guarantee safe production with Shunxin fertilizer granulator?

Shunxin granulators for fertilizer are designed and manufactured with high quality and durability, so their competence is undisputed. But it is us who operate the machines with correct procedures can ensure the production safety. There are some tips for you to learn about how to make safe production with Shunxin fertilizer pelletizer.

- There is an instruction manual with the machine after your purchase, so you can read and get familiar with its structure and performance.

- Don’t touch the driving parts of the machine, because they work with very high speed.

- Don’t touch the equipment after it is powered on by electricity and during the operation of granulation.

- Make sure there are no hard objects mixed in the raw materials, like pebbles or metal briquettes, since you don’t want them enter your granulator.

- Regular maintenance can make sure the machine operates under perfect condition. You can clean the machine, and check for the loosen bolts and worn parts. Fix and replace the broken parts in time.

Where can you use the fertilizer granulation machine?

Fertilizer granulator can turn powdery fertilizers into granules. Our granulators use dry granulation technology and wet granulation technology for making the fertilizer powder into granular fertilizers. You can use our fertilizer granulation equipment for organic fertilizers granules production line or compound fertilizer pellets making.

In your fertilizer production plant

Generally, our fertilizer granulator is often used for fertilizer manufacturing plant. For your organic fertilizer granules production, there are wet type organic manure granulators for you to choose. They can process the organic materials, whose moisture content is between 25%-35%. While, for your dry powdery compound fertilizer granulating, our fertilizer roller compactor machine can process your dry powder, whose moisture content is under 5%. It can shape your dry powder by pressing.

Thus, whether for your organic or compound fertilizers production, it is helpful for you to equip with a granulation machine. What’s more, our fertilizer pelletizing machine can meet your different requirements. Whether your materials is dry or wet powder, we have suitable machines to recommend for you.

In your animal farm

It is a good choice for you to apply fertilizer machines in your animal farm. The animal manure waste is not only a problem for your animal farm, but also a waste for recycling. You can try to process them into available fertilizers. Here we have complete organic animal manure fertilizer making machines. It can help you turn animal waste into fertilizers for commercial use. And the granulation machines plays an important part for turning animal manure composts into commercial granular fertilizers.. According to your different requirements on production capacities,there are also various equipment for you to choose. Meanwhile, for your pelleted organic animal manure processing, we can also provide complete processing machinery for you.

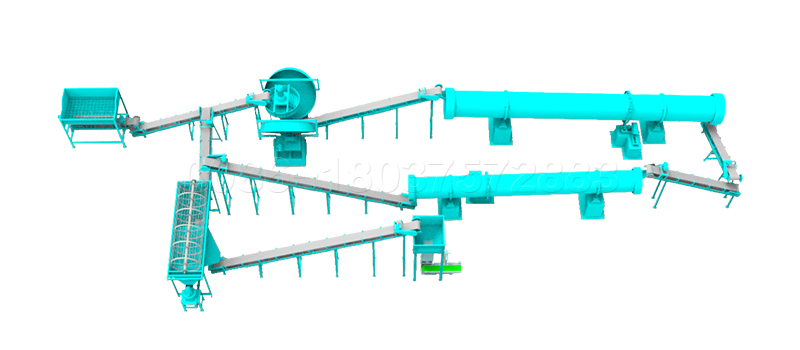

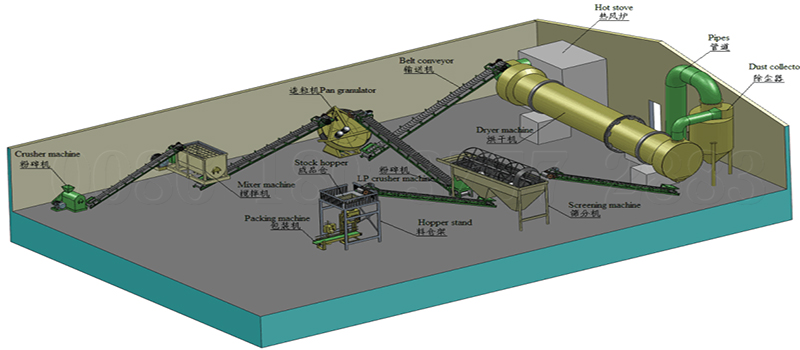

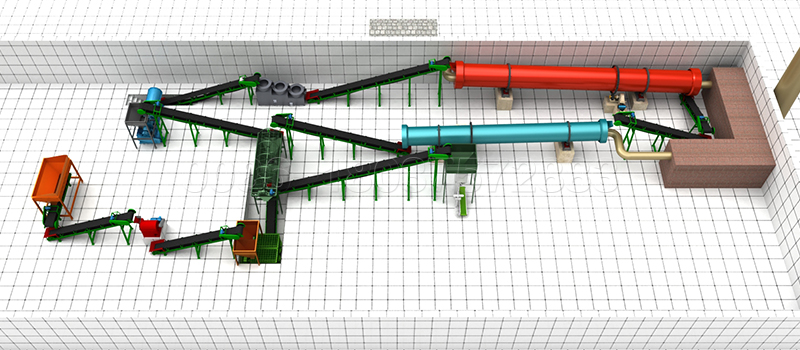

Shunxin fertilizer granulation lines for your fertilizer granules making plant

Expect for the fertilizer granulators, there are also some fertilizer production lines for you to choose. Our granulation machines are suitable for your organic fertilizers granules making. Whether for your animal waste fertilizer recycling or small scale organic fertilizer production. We recommend you different equipment configurations including the fertilizer granulators.

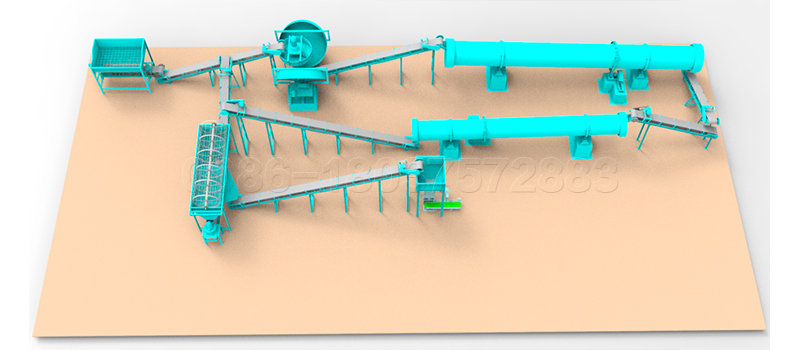

Small scale new organic fertilizer granulation line

Making organic fertilizer granules, Shunxin recommends you our new designed organic fertilizers granulator for your granulation. Before the granulating, you had better make sure that your organic fertilizer materials are powdery. Or you should use an organic fertilizer crushing machine for making fine powder. And then the new granulator will turn your powdery organic fertilizers into high quality organic fertilizer granules efficiently. For your commercial fertilizer manufacturing, it will be more efficient for you to use the drying and cooling machine for processing the granulated organic fertilizer better. After the drying and cooling, our packing machine will bag your organic fertilizer products efficiently with high accuracy. Meanwhile, because of your requirements on the small scale, we provide you single bucket fertilizer packaging scale.

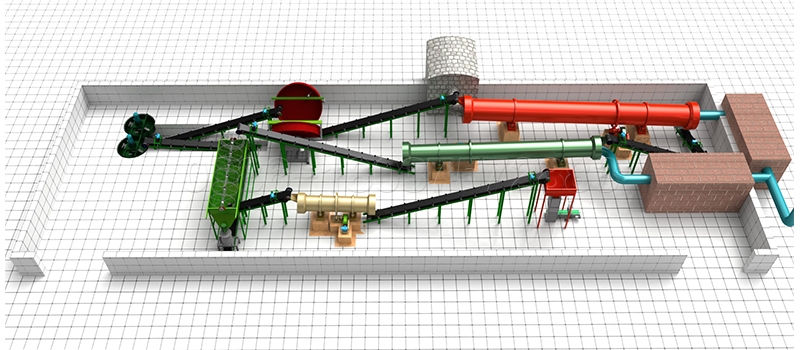

Pan type organic cow dung fertilizer granules making line

Utilizing cow dung for making fertilizers, we have organic cow dung manure compost making machines for you to prepare available fertilizers. There are organic cow dung compost turner and fermentation tanks. These two types of organic compost making machines can help you turn fresh organic cow dung manure waste into available organic fertilizers. According to your different requirements, you can choose trench type composting machine or windrow compost turner. With these machines, your organic cow dung manure compost will be finished in only 20 days.

After the composting, our cow dung manure compost grinder will crush the composts into fine powders. And then the conveyor will send the powdery cow dung into granulation machines for making granules. Our pan granulator has high granualtion rate. Meanwhile, it is applicable for you to control the size of pelleted organic cow dung fertilizers. Then, the pelleted organic cow dung can be dried, cooled, screened and packed.

This whole set of organic cow dung fertilizer granules making machines can turn your fresh organic cow dung into high quality fertilizers granular. Meanwhile, if you have other requirements on the production capacity or equipment configurations, we can customize for you.

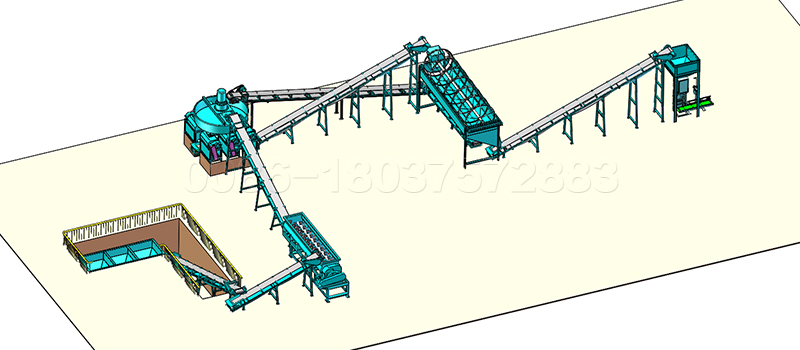

Dry type double roller extrusion granulating line for compound fertilizer granules making dedicated

Our granulators are suitable for not only organic fertilizer granulation line, but also can turn compound fertilizer powder into granules. The compound fertilizer granules manufacturing process has some differences with the organic fertilizer granulation line. It do not need to compost firstly. Moreover, The raw materials for our compound fertilizer granules manufacturing should be powders. If your materials are compound fertilizer powders, you can use a batching equipment for batching the fertilizer powders well. And then the mixer will blend them evenly for granulating. Generally, for your dry powdery compound fertilizer granulation line, the double roller granulator is a good choice. It can pelletize your powdery fertilizers by the extrusion force. After the dry granulating, you can send the granulated compound fertilizers into screening machine and then pack them directly.

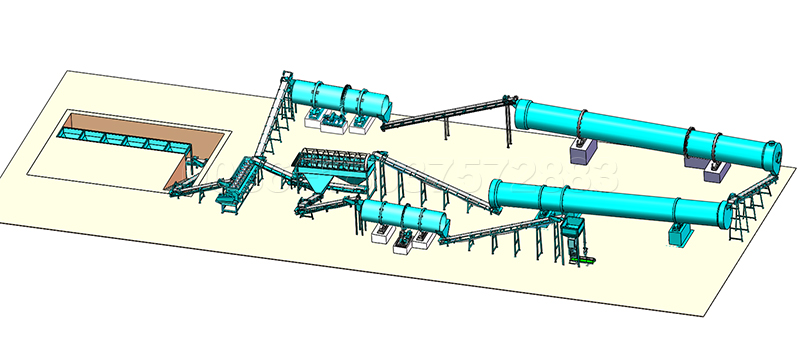

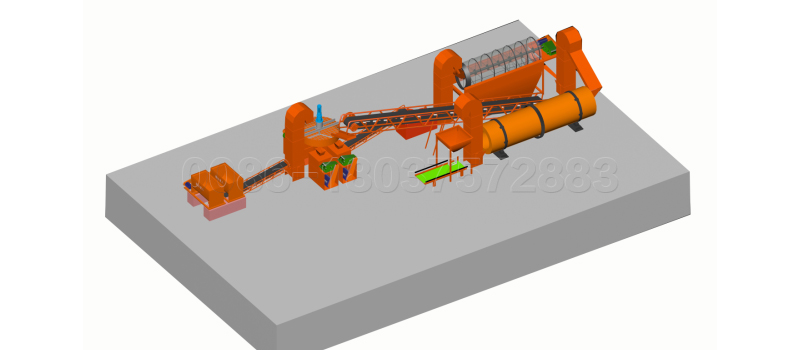

Drum type compound fertilizer granules production equipment for large scale fertilizer manufacturing

For your large scale compound fertilizer granules production, we suggest that you can use a drum granulation machine for pelletizing. Comparing with the pan and roller type fertilizer granulators, this rotating drum granulator has larger production capacity. While, this machine can also turn your compound fertilizer powder into granular fertilizers by wet granulation technology. It utilizes the rotating cylinder for turning powder to granules. Thus, after the drum granulation, it is necessary for you to use the drying and cooling equipment for processing the granulated compound fertilizers. In your large scale fertilizer production plant, it will be helpful for you to screen and coat the fertilizer granules. You can add some liquid coating agents for cotaing screened compound fertilizer pellets by rotating coating equipment. Meanwhile, we also have double buckets fertilizer granules products bagging machine and ton packing equipment for packaging with large production capacity.

How to choose a good fertilizer granulator with reasonable price?

The cost-effective fertilizer granulation machine is of low energy-consuming, high yield capacity, and long service life. Shunxin heavy industry machinery has dedicated all the powers and resources to promote and manufacture that kind of pelletizers for you. We are the leading brand of the fertilizer equipment manufacturer. Furthermore, Shunxin has the most experienced experts and engineers.Besides, there are complete work procedures foe you. So, you can count on both our products and services.

Fertilizer granulator Shunxin offers is all capable of doing heavy-duty work. Because we employ the most durable alloy to produce them. Order now and you will get a good discount! No matter which country are you in, India, Malaysia or South Africa, or other distant towns and cities. Shunxin Heavy Industry will always deliver the intact machines to you. To know more about how much does fertilizer granulators cost, and the online purchase, feel free to consult us any time you like.

Latest industrial design solutions for our fertilizer manufacturer customers

Shunxin is an established fertilizer equipment production factory. We have been dedicated in fertilizer equipment research and development over 15 years. Therefore, you can buy quality fertilizer granulator machines and efficient fertilizer production lines. What’s more, our machines have been sold at home and abroad. There are many successful transition cases of fertilizer equipment in our company. You can know about the latest deisgn solutions of fertilizer production line for the customers from all over the world.

6t/h Ammonium Nitrate Fertilizer Granulator Machine for Sale in South Africa

Guinean Chicken Manure Fertilizer Pellet Making Machine for Sale

10 TPD Bentonite Granules Production Line for Customer in Kenya