The Shunxin double roller granulator is an important compound fertilizer pelletizer. It is a kind of extrusion machine, adopts physical strength to condense and granulate the dry materials. The pellets it makes are more intense compared to the products of other granulators, so no worries if you want to pile them up. The double roller extrusion granulator can work under normal temperature, but yields high granulation ratio. If you have several of these cost-effective granulators, they will surely facilitate your fertilizer plants with high work efficiency.

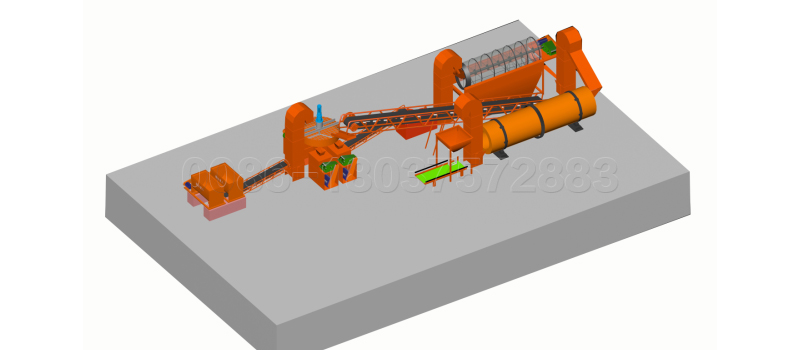

Normally, our double roller fertilizer granulator is sufficient for the work, but you can always compose other fertilizer making machines with it to form a production line with continuous work capacity. The proper machine should consist of fertilizer crusher, automatic fertilizer dispenser, screener, conveyor, pellet polishing machine, coating machine, packing machine, etc. We can adjust the scale of the production line to your preference.

Double Roller Granulator

- Model: SXJZ-1T

- Granule Diameter (mm): 3-10

- Roller Sheet Size(mm): 150*220

- Dimensions(mm): 1450*800*1450

- Color: blue (support tailor-made products )

New type of Shunxin double roller granulator is available for you to choose

Because the perforated roller granulator is so practical and important in the granulation of compound fertilizers, we have been working hard to improve it to better designs. Compared with the traditional double roller press granulator, the new type machine possesses the following advantages:

- Add stirring device to the feeding inlets. They can make sure the raw materials are fed into the machine with constant speed.

- Add self-clean device to the body frame of the machine, it can prevent the raw materials from sticking to the rollers.

- The gaps between the rollers can be adjusted according to the levels, that will make sure the gaps are well-proportioned, and the operations more convenient.

- The rollers are verified by the splines of the gears, so the rollers will work with no misplacement.

The new developments make the double roller pressing fertilizer granulator machine much easier to operate and maintain. It is a better choice for you to make compound fertilizers.

extrusion granulator

- Model: SXJZ-1.5T

- Granule Diameter (mm): 3-10

- Roller Sheet Size(mm): 150*300

- Dimensions(mm): 1450*850*1650

- Color: red(support tailor-made products )

Why choose Shunxin heavy industry machinery as your double roller granulator manufacturer?

Shunxin heavy industry machinery has been dedicated to the designing and manufacturing of fertilizer making machines for over thirty years. We have the most skilled experts and professional team, with their efforts we provide you with a wide range of multifunctional fertilizer roller press granulators. Our pelletizers are made with high quality corrosion-protective, wear-resistant materials, they can serve you for a very long period of time. Besides, the roller sheets of the granulators are all made by ourselves, so you can choose to change the pattern of the sheets to meet your specific production needs, that’s much more convenient than others. High-end double roller squeezing granulating machines are now for sale. No matter where you are, India, South Africa or Turkey, or any other countries, if you are searching for a reliable roller compaction granulation machine supplier, we are at your service anytime you want.

double roller extruder pellet machine

- Model: SXJZ-2T

- Granule Diameter (mm): 3-10

- Roller Sheet Size(mm): 185*300

- Dimensions(mm): 1630*850*1650

- Color: red(support customized products )

What kind of materials can you process with Shunxin double roller granulator?

Shunxin extrusion spheronization equipment can be widely used in many businesses. It can granulate pellets with a number of different kinds of raw materials. Here are some of the applications for you to refer to.

- Compound fertilizer granulation. The extrusion granulation was initially applied to create potassium chloride pellets, so you can use the extruder pellet machine to produce compound fertilizers and BB fertilizers. You can pelletize any NPK fertilizer materials and dried organic materials with it, especially for the granulation of tombarthite, potash fertilizer, ammonium bicarbonate, etc. It also can produce granules of different concentrations and usages, just change the formula of the mixed materials before putting them into the machines.

- Solid chemicals granulation. Some of the solid chemicals can be granulated by our pellet extruder, the working principle is similar to the compound fertilizer granulation, such as antioxidant, cyanuric acid, oxides, etc.

- Pharmaceutical granulation. Since Shunxin fertilizer double roller extrusion granulation machine works based on physical extrusion, you can also use it to produce some of the medical tablets, and those little granules used to fill in the capsules.

- Daily commodity. Some chemical products which is used in daily life can also be granulated by our machine. Like pigments, detergents, some cosmetics, salt granules, hops, and so on.

- Industrial dust recovery materials. Those powders and dusts left during processes can be granulated and used as materials again, such as coal dusts, metallurgy leftover powders, etc.

As you can see, Shunxin double roller press fertilizer machine is very versatile, it can deal with materials which beyond fertilizers. Surely you can find a good way to employ it.

double roller extrusion spheronization equipment

- Model: SXJZ-2T

- Granule Diameter (mm): 3-10

- Roller Sheet Size(mm): 300*300

- Dimensions(mm): 1850*850*1650

- Color: red(support customized products )

How does a double roller granulation machine help you produce the compound fertilizer granules?

Using the fertilizer roller compactor for granulating, you can get oval compound fertilizer granules. This machine utilizes the dry extrusion granulation technology for pressing the dry compound fertilizer powder into granules. And, because of the dry powder granulation, you do not need to dry and cool the pelleted compound fertilizers. Then, for your commercial compound fertilizer granules manufacturing, it is applicable for you to equip with a fertilizer screener equipment. This machine can help you classify the pelleted compound fertilizers. You can get fertilizer granules, powdery compound fertilizers and the granules, which are too big. It is suitable for you to re-crush big the compound fertilizer granules and granulate them again. Meanwhile, the unpelletized compound fertilizer powder can be re-granulated. And then our fertilizer bagging equipment will pack your compound fertilizer granules efficiently with high accuracy.

The instructions of how to maintain Shunxin double roller granulator

Shunxin compression roller granulator works basically with powerful physical extrusion. The machine itself is designed and manufactured for heavy-duty purposes, but the wear is there every time you start the machine, so correct operation and proper maintenance is necessary to prolong its service life and ensure a steady performance.

- When feed the materials into the machine, make sure they are fed along the length of the roller with constant speed and quantity. If the feeding is uneven, the roller surface will become rough, which will affect the function of the machine, and the product sizes will be uneven.

- The wear of the roller sheet is inevitable, so you should check them regularly and maintain them in time. If it wears out, then you should change it. Shunxin company have the techniques to make you new roller sheets, so you can get it renewed easily. Also, if the model of the granulators are the same, their roller sheets can replace one another.

- You should start the machine without load, make sure there is no materials in the granulator before you start it.

- Screen the materials and get rid of the hard objects, they may break the roller shaft.

- Grease the driving part with yellow dry coating oil to reduce wear. The gears should oiled every time you start the machine. The chain and chain wheel, a week a time. As for the bearing block, three months a time should be enough. And you should change the gear oil which maintains the decelerator, about four months a time.

The form of dimensions of double roller granulator

|

Model |

Power(kw) |

Pellets Diameter (mm) |

Roller Sheet Size(mm) |

Overall Size(mm) |

|

SXJZ – 1T |

Pellet Diameter ≦4.5mm : 11

Pellet Diameter >4.5mm: 15 |

3 – 10 | Φ 150 x 220 |

1450 * 800 * 1450 |

|

SXJZ – 1.5T |

Pellet Diameter ≦4.5mm : 18.5

Pellet Diameter >4.5mm: 22 |

3 – 10 | Φ 150 x 300 |

1450 * 850 * 1500 |

|

SXJZ – 2T |

Pellet Diameter ≦4.5mm : 22

Pellet Diameter >4.5mm: 30 |

3 – 10 | Φ 185 x 300 |

1630 * 850 * 1650 |