Hops pelletizing equipment can make long lasting hops granules for you to store. People can use hops as medicine or green fertilizer. But it is well known by its irreplaceable ability to make high quality beer. So people often call it “the soul of beer”. When we refer to hops as “beer flower”, we really mean the inflorescence of the female plant. We also call it hops cone because of its appearance. Hops can be used directly to produce beer. Or you can use a hop pelletizer to make good hops pellets. Generally, hops pellets are 20% to 30% stronger than the same variety in cone form by weight. If you have a brewery, it is very cost-effective and convenient that you have your own hop pellet mill. There are lots of hop pellet machine for sale, but Tongda company can present you the best hop pelletizer machine.

Model : TDJZ – 1T

Power(kw) : Pellet Diameter ≦4.5mm : 11; Pellet Diameter >4.5mm: 15

Pellets Diameter (mm) : 3 – 10

Roller Sheet Size(mm) : Φ 150 x 220

Overall Size(mm) : 1450 x 800 x 1450

Professional hops pelletizing equipment for sale in Tongda company

Are you looking for high-end hop pellet mill for sale? Do you want to reduce your hop pelletizer cost to more reasonable level? Tongda heavy industry machinery should be your best choice. Our machines can promote your hop pelletizing work, with a considerable discount if you order now! No matter what scale your hop pelleting facility is, we always have the suitable model for you. Small hop pelletizer for small hop pellet mill, and big machines for big plants. We can even tailor the hop pelletizer equipment to meet your specific demands. With our powerful technique team and sophisticated designs, that should be no problem. We also have a thorough work procedure, if you want to order a hops pelletizer to New York, we will send it to you intact. No matter which country are you in, we will bring you the best service.

Model : TDJZ – 3T

Power(kw) : Pellet Diameter ≦4.5mm : 37; Pellet Diameter >4.5mm: 45

Pellets Diameter (mm) : 3 – 10

Roller Sheet Size(mm) : Φ 300 x 300

Overall Size(mm) : 1850 x 1100 x 2050

Four unique effects of the hops pelletizing equipment products

When German brewer first put the hops into their barrels in 1079, they became an important material in the brewing process since then. Tongda pelletizers can make granular hops whose functionality is as good as the fresh flowers. Here we will introduce the effects they can cause.

- Hops pellets add refreshing aroma and bitterness into the beer. The fragrance of the hops and the clean aroma of the malt together bestow a unique flavor to the beer.

- Hops pellets are naturally antiseptic, there is no need to add toxic preservatives into the beer.

- The isohumulone in the hops and foaming protein in the malt can form into the beer foam. High quality of hops granules and malt can produce the white, fine, smooth, rich and long-lasting foam.

- The hops can precipitate and separate the protein in the wort when you boil it. Hops pellets can clear the wort, and make pure beer out with it.

Pelletizing hops at home with Tongda hops pelletizing equipment can be simple and efficient

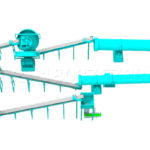

You wanna make your own beer at home? We can provide you with our excellent pellet making equipment for that. Here are the simple steps. First, put the hops into the Tongda crusher, it can shred the hops to little pieces, making the following steps easier and preserve the hops properties to the maximum. Then, add the hops powder into Tongda granulators. The proper machines should be double roller granulator or flat die pelletizer. These two types of pelletizers can process the hops pieces into small concentrated granules which you can easily apply. furthermore, we suggest you use a Tongda mixer machine to blend the hops powder before putting them into the granulator. That will make the powder obtain a specific and consistent alpha acid level. After the granulation, you should store the granular hops in the sealed packages, and avoid the exposure under direct sunlight or high heat.

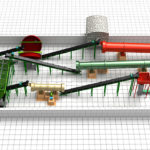

How to pelletize hops with a full set of granule production line?

Different from family workshop, hops pelletizing process with commercial hop pelletizer in a big scale plant needs other collaborating machines. Tongda company has developed series of production lines to serve different kinds of processing purposes. The first few steps are similar to the home made process, but in larger scales. You need use Tongda crusher and mixer to create uniformly composed hops powder. Then use Tongda hops pelletizing equipment to produce hops granules. After the mass granulation, you need Tongda rotary drum cooler to rapidly chill down the pellet products. By doing this, you can prevent the heat from causing the loss of too many volatile aromatic compounds. So the final products can be as fresh as the raw materials. Then you can pack them up, seal them in the vacuum packages.

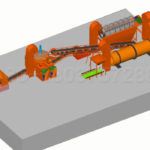

Model : Kp-400c

Power(kw) : 37

Capacity(t/h) : 1.5 – 2.5

What are the important things during the hops granulation you should note?

Hops are important to the brewing, many brewers therefore prefer hops cones over hops pellets, because the cones are raw, intact, natural ingredients. The hops pellets, however, are processed by hops pelletizing equipment. People think the processing may eventually affect the naturality of the beer. That’s why we need to notice few details that can preserve the properties of hops pellets, make them as good as the hops cones.

- When you shred and mix the hops cones by Tongda mixer, the lupulin sacs will be ruptured, the materials inside will mixed with the hops powders, too, making the powder gummy. They can be used both as the binder and protective coating. So even you are dealing with dry hops cones, don’t add water into the materials unless they are extremely dry.

- The temperature can affect the quality of hops pellets tremendously. When you do the crushing, mixing and compression granulating, make sure do it at relative low and even speed. If the process still generate too much heat, add some liquid nitrogen or something else to cool the materials down.

- The hops pellets can be stored for a very long time. If you can seal them up in vacuum bags after granulation and put them into cold storage, they can last much longer.