Shunxin 1-3 t/h small scale organic fertilizer production line for sale

Would you like to start your organic fertilizer business? If you are a fresher in organic fertilizer industry, Shunxin suggests you can have a try on small scale organic fertilizer plant. Small scale organic fertilizer production line is similar to other types organic fertilizer production lines, which can make organic wastes into fertilizer. In general, it is popular in big farm, small sugar industry and winery. Shunxin small scale fertilizer production machines could help you process your agricultural waste and poultry manure ecologically. What’s more, As a professional fertilizer equipment manufacturer, Shunxin can provide you whole set of organic fertilizer machines for your small scale production line. If you have interest in small scale fertilizer industry, please contact us in time. Our engineers will design a suitable small fertilizer making plan for your business.

What is the main process in your small scale organic fertilizer production process?

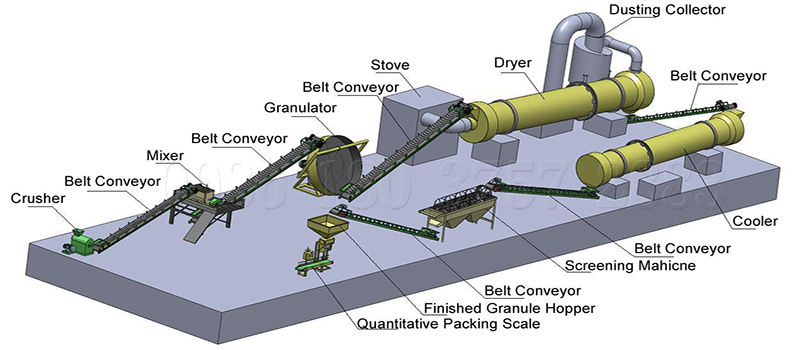

Generally speaking, the main small scale organic fertilizer making flows includes fermentation process, crushing process and granulating process. Now Shunxin experts will introduce the detailed information for you as follows.

Fermentation process

On account of there being pests and diseases in fresh chicken manure, cow manure, vermicompost, horse manure, it is necessary to ferment your organic materials. Fully fermentation to your organic materials can promise the fertilizer quality. In general, your organic fertilizer materials usually need fermenting for around one month without the help of compost windrow turner. So, if you want to shorten the period, Shunxin fertilizer composting turner is a good choice.

Crushing process

This process is an important procedure both in granular fertilizer production and powdery fertilizer making. At the beginning, you should crush your materials before materials efficient fermentation. Next, before materials granulating, there is also need to crush organic fertilizer materials again. That is to meet the requirements of fertilizer granulation equipment. The company designs new type vertical crusher, semi-wet materials crusher. Both of the fertilizer crush machine could smash your high moisture materials.

- Model: SXSF-40

- Power: 22kw

- Dimensions: 1200*1350*900

- InLet Size(mm): 400*240

- Capacity: 1-1.5t/h

- Crushing Granularity(mesh):50

- Color: red (can be customized)

Granulating process

If you plan to enter into granular small scale fertilizer industries, the granulating process is indispensable during your fertilizer manufacturing. In general, granulating process is to use fertilizer granulator pelletize your powder materials into fertilizer pellets. Therefore, it is necessary to assemble fertilizer pelletizing machine for your small scale fertilizer production. Now Shunxin could provide you disc granulator, rotary drum gear granulator, new type organic fertilizer granulator, rotating granulator for you. They are all have over 95% balling rate and adopt wet type granulation technology. Thus, you should prepare water or additive when fertilizer is balling. The most important is your fertilizer productivity can be greatly improved with Shunxin granular fertilizer machine.

Organic fertilizer granulating equipment

- Model: SXJZ-1000

- Installation Angle: 2°-2.5°

- Capacity: 2-4t/h

- Total Power: 75kw

- Dimension: 4700*2350*1600mm

- Application: pelletizing organic fertilizers

Packing process

There is the last procedure that is to pack your fertilizer into bags. You can choose to employ labor force to finish this process. However, if you want to enhance fertilizer making speed, Shunxin still suggests you buy a fertilizer bagging machine. The automated fertilizer packaging machine can independently do fertilizer bagging work without one person. Moreover, you could choose to pack your fertilizer in 5kg, 8kg, 10kg, etc.

- Model: SXH-50

- Function: packing and weighing materials

- Weight: 500kg

- Voltage: 380v

- Packing Speed: 3-4bags/min

- Degree of Automation: fully automatic

The above contents are the main process in a complete small scale organic fertilizer production process. If you want to learn more detailed information, please contact us in time.

How to do your compost fertilizer manufacturing business in small plant?

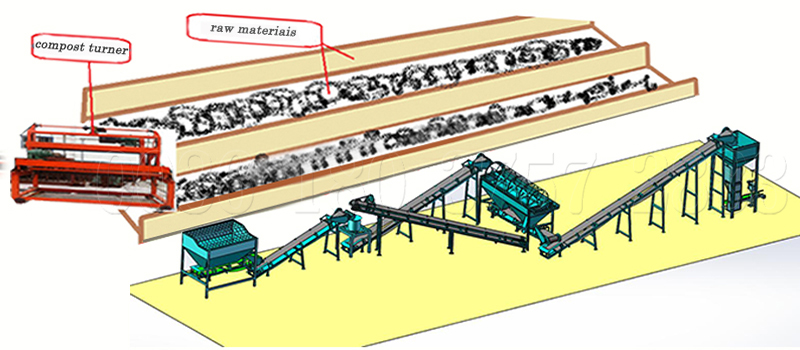

Making organic compost fertilizer, you had better know what are the processes for composting efficiently. For your fertilizer business, it is helpful to equip some machines for making your production process more efficient. In you small plant, we have small powdery organic compost fertilizer making line. Here Shunxin provide you popular composting plan for your reference.

Dewatering the high-moisture organic materials

Because of the high moisture content of organic materials, you should separate the liquid from the solid materials. Shunxin has dewatering machines for you to lower the moisture content of organic waste. There are two types of separator for you to choose. According to your production capacity, materials and preference, we will provide you a suitable equipment.

Using a small compost turner for composting quickly

For your small scale composting, we recommend you the small moving type windrow turner. Its production capacity is as same as the crawler type turner. While, it is easier for you to operate. It can move and turning conveniently. Meanwhile, this machine will not take you too much space. If the area of your plant is small, this organic composting turner machine is a good choice. What’s more, it is the most economic equipment among all the organic compost turners.

Pulverizing the composted organic fertilizers for making fine powder

To make commercial organic fertilizer, turning the composted organic fertilizers into high quality fine powders. Shunxin has composted organic fertilizer pulverizers for your reference. There are semi-wet type and new vertical organic fertilizer crushing equipment for fertilizer powder making. The crushed compost powder is fine enough for selling.

Screening the crushed organic compost

This screening process is aimed for selecting the unqualified fertilizer powder out. And then you can re-crush the unqualified organic fertilizer powder.

Finished organic compost powder packing

In the small compost fertilizer making line, it is time for you to pack the powdery products. Shunxin has dedicated powdery fertilizer bagging equipment. Because of your manufacturing business is small scale, we recommend no bucket or single bucket packaging equipment for you. Both of them can pack your organic fertilizer powder efficiently.

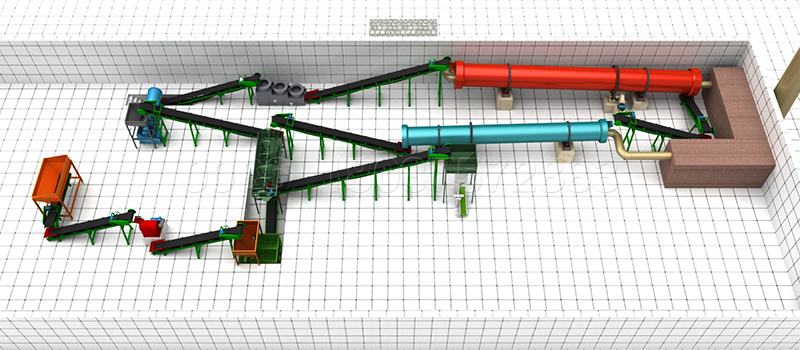

Complete processing equipment for your small organic fertilizer plant

Shunxin is a professional and experienced organic fertilizer making machine manufacturer. There are various organic fertilizer production plans. For your small scale organic fertilizer plant, we have 2 types of organic fertilizer making systems for you. They have different equipment configurations and prices.

Main equipment for small organic fertilizer company

The two key processes of organic fertilizer granules manufacturing are composting and granulating. Thus, it is necessary for you to equip with a composting turning equipment and granulator. While, the materials for granulation must be powders. You had better use an organic compost grinding machine for making composted organic fertilizers into powders. With these 3 machines, you can get organic fertilizer granules efficiently. And, for your commercial company, we suggest that you equip with a fertilizer packing equipment. This machine will pack your products conveniently.

Full set of small organic fertilizer production line with small production capacity

For your small yield organic fertilizer making requirements, we have small size organic fertilizer production line with small capacity. From composting to packing, we have suitable machines for your reference.

Small scale organic compost powder making machine

The small scale organic compost fertilizer powdering machine includes the compost turner and manure grinder. Shunxin recommend you the groove type composting machine and semi-wet crusher. The groove type turner is a widely-used trench composting machine. Using this machine for composting, you should build some grooves for placing the organic waste. And then operating the trench compost turner for turning the organic materials. 20 days later, you can get well composted fertilizers. Then, the semi-wet materials pulverizer will turn the composts into powders for granulating. Shunxin semi-wet crusher has many specifications. We will recommend you the most suitable one according to your production capacity.

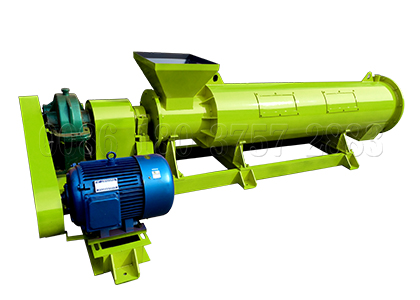

Shunxin new patent organic fertilizer granulating machine

The new patent organic fertilizer granulator is a new designed machine for organic fertilizer granules making. It uses advanced design for pelletizing. This machine can process 1 ton to 15 ton fertilizer pellets per hour. If your ideal production capacity is larger than 15 ton per hour, we also have other granulators for you. Meanwhile, there are also full set of fertilizer production machines for you. For your information, it is alternative for you to equip with a polishing machine. The polishing equipment can make your fertilizer granular rounder.

Small size rotating drying and cooler

Generally, the organic fertilizer granulating equipment takes advantages of wet granulation technology for making granules. Thus, the granulated organic fertilizers are wet. Shunxin rotating dryer and cooling machine can lower the moisture content and temperature of processed fertilizer granules.

Rotating screener equipment and coating system

In your high quality organic fertilizer production line, a screening machine can help you improve the fertilizer quality. It can classify the processed products. The unpelletized powder can be granulated again. Meanwhile, it is also applicable to re-crush the big granules and granulating again. And the coating machine will make the fertilizer more beautiful.

Single bucket organic fertilizer granules packaging scale

Bagging is the final process in a fertilizer making line. Our single bucket fertilizer packing machine has one bucket for weighing the products. It is suitable for your fertilizer plant with small capacity. And equipping with a sewing machine, the fertilizer packing will be more efficient.

Which type small scale compost turner can perfectly help you finish organic materials fermentation?

As you know, the first key process in small scale organic fertilizer production line is fermenting organic materials. Thus, organic fertilizer fermentation plays an important role in organic fertilizer manufacturing process. Then based on all clients demands, Shunxin designs different fertilizer compost turners for organic fertilizer production plants. At present, there is groove type compost turner, crawler type composting machine, and self propelled compost turner for you.

Groove type compost turner with automatic lifting device

This type organic turning machine needs work in a groove. That is to say you should firstly increase a fermentation groove in your small fertilizer plant. Then it is suitable for fermentation of livestock manure, sludge and garbage, filter mud from sugar mill, worse slag cake and straw sawdust. Moreover, during fermentation, the speed is 2-3 meter in one minute. After finishing work, its speed is 30-50 meters per minute. Therefore, it can quickly help you regularly turn your fermenting organic materials.

- Model: SX-3000

- Main Power: 18.5kw

- Mobile Power: 1.5kw

- Lift Power: 1.1kw

- Application: Turning the compost on the groove

Smooth operation of crawler type composting machine

Shunxin crawler type small windrow turner belongs to the ground pile fermentation mode. Here you should pile up your materials into a stack before using the turning machine. Then, our crawler type turner will regularly help you to turn the organic materials under aerobic conditions. What’s more, it has the function of crushing materials, which could save your investment in fertilizer crusher. In addition, it is the smoothest operated turning machine among all type fertilizer compost turning machine.

- Model: SXLDF-2300

- Color: Yellow(can be customized)

- Working Speed: 6-10 m/min

- Durning Width: 2300mm

- Durning Height: 600-1000mm

- Application: Turning organic wastes piles

Moving type small scale composting machine

You can call it self -propelled compost turner, which is dedicated for small bio organic fertilizer production line. There you only need to employ one person to operate it. Similar to crawler type turner, the materials are piled us long strip before using self propelled organic turning machine. Furthermore, it is suitable to work both in the workshop and open space. So, if you want to spend less money, you can choose a large open site for your fermentation process.

- Model: SX-300(can be customized)

- Color: Yellow

- Size: 4930×1620×2660mm

- Application: Turning organic wastes piles

- Feature: Also can be used as a forklift

All in all, Shunxin small compost turner could help you to quickly finish your materials fermenting within 15 days. However, if it is in winter, the time may extend to around 20 days. If you have need in compost turner, Shunxin is the best choice. Please feel free to inquiry us for the latest quotation.

Small granulator recommendations for 1-3 ton per hour organic fertilizer granulation line

There are many specifications of fertilizer pellet making machine for your different requirements. They can meet your different requirements on the production capacities. Our pan granulation machine and new organic fertilizer granulation machine are popular in organic fertilizer making plants.

SXYZ-2800 fertilizer pan granulator for sale

Pan type organic fertilizer pelletizer utilizes centrifugal force for granulating powder into granules. This machine has many sizes and production capacities. Its smallest size can produce 0.3 ton per hour. Generally, for your small scale fertilizer granulating, our SXYZ-2800 is a good choice. It can process 2-3 ton fertilizer powders per hour. Meanwhile, you can also control the size of pelleted fertilizer by adjusting the rotating speed and disk tilt angle. Moreover, this machine is economic but multi-functional.

Pan type fertilizer granulation machine

- Model: SXYZ-2800

- Edge Height: 450mm

- Rotary Speed: 14(r/min)

- Capacity: 2-3t/h

- Total Power: 11kw

- Dimension: 3200*2200*3000mm

Hot sale SXJZ-600 new organic fertilizer granulation equipment

Besides the pan granulator, you can also choose our new patent granulator. We designed it for granulating organic fertilizers dedicated. Meanwhile, compared with the disk pan granulator, the granular fertilizers made by this new granulator is harder. It makes sure that the organic fertilizer pellets will be not easy to be loosen. For your 1 ton per hour organic fertilizer granules production requirements, our SXJZ-600 will be suitable for you. It is the smallest size of the patent organic fertilizer granulation machines.

- Model: SXJZ-600

- Installation Angle: 2°-2.5°

- Capacity: 1-1.5t/h

- Total Power: 37kw

- Dimension: 4100*1600*1150mm

- Application: making organic pellet fertilizers

How to start your small scale organic fertilizer plants with Shunxin fertilizer machinery?

Commonly, it is not easy to start a new business. And it is the same as fertilizer business. Here, Shunxin experts give you some proposals about how to establish small scale fertilizer manufacturing company.

- Firstly, it is essential for you to make a market research. Because you should to know which fertilizer has a better sale in fertilizer market.

- Secondly, choosing a suitable site to build your small scale organic fertilizer making plant.

- Thirdly, mastering the technology of organic fertilizer production, which need you to employ some fertilizer technical stuffs.

- Fourthly, it is time to find a reliable a fertilizer making machine manufacturer.

- Lastly, the invest capital is also a key factor.

In a word, after preparing invest money, choosing suitable fertilizer making equipment and factory site, you can begin to carry out the small scale fertilizer plant ideas.

What does your small scale organic fertilizer production line cost?

As for the question, all fertilizer manufacturers will want to ask. To be honest, we just provide you the estimate cost to open small scale fertilizer industry. Because there has too many influential factors. But as long as you choose Shunxin as a cooperation partner, our engineers will design an affordable project for you. In addition, Shunxin Heavy Industry could supply you whole set of small fertilizer production machines. Thus, you can save the time cost to find different equipment.

Furthermore, the company has its own fertilizer equipment factory and good reputation in China. The most important is you can get quotation with factory price. Besides, there may be great discount in Double 11 or other festivals. Therefore, if you have interest in Shunxin Heavy Industry, please let us know in time.