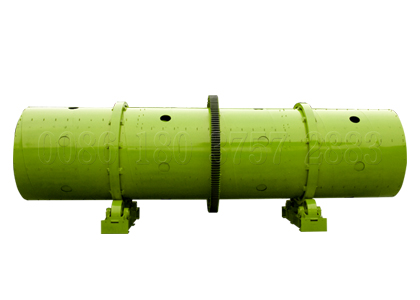

What is a rotary drum granulator?

The rotary drum granulator is a kind of shaping machine, it can make the powdery fertilizer materials into specific granules. The rotary drum machine granulator is mainly used in fertilizer granulation process. And it is considered one of the most important equipment in the use of compound fertilizer production. Though the granular drum machine can work independently, you can also pair it with other fertilizer making machines to assemble a complete production line of rotary system for fertilizer, that you can use to achieve mass-production with high efficiency. The proper equipment include fertilizer crusher, mixer, dryer, cooler, granulator screens and dispenser, etc.

rotating granulator

- Model: SXZGZ-1240

- Power: 5.5kw

- Diameter: 1200

- Installation Angel: 2°-5°

- Rotary Speed: 17(r/min)

- Capacity: 1-3 t/h

What convenience a rotary drum granulator can provide?

The rotary drum is large in size, so it can deal with a lot of materials simultaneously. And the pelleting ratio is up to 70%! So it is very suitable for large-scale fertilizer production plants. In the mean time, the rotating drums only consume relative low energy while working. So they are a high cost-effective choice. The special design of the interior of the rotary granulator machine is adhesion-proof. There will be no materials attach to the inner wall during granulation. So it is easy to maintain with less cost. The pellet drum is also versatile, it can do both cold or heated granulation. You also can produce compound fertilizers of your desired concentrations with it. Because of the granulation technology, The pellet products are of less moisture, so you can dry them much more easily with higher work efficiency and low labour burden.

rotary granular drum machine

- Model: SXZGZ-1560

- Power: 11kw

- Diameter: 1500

- Installation Angel: 2°-5°

- Rotary Speed: 11.5(r/min)

- Capacity: 3-5 t/h

Would you like a high-end rotary drum granulator?

Since the fertilizer rotary drum granulator is very helpful in the compound fertilizer production, you might want one to facilitate your plant. Shunxin Heavy Industry Machinery is one of the foremost manufacturers of fertilizer making equipment in China, so there are plenty of high quality rotary drum fertilizer granulators of various sizes and models for you to choose. We can also customize the machine for your specific demands. If you want more details about the rotary drum granulators for fertilizer making and their prices, you can always consult us anytime you want. Wherever you are, Korea, malaysia, cities mumbai and ludhiana in India, or any other distant countries and towns, we will do our best to serve.

fertilizer drum pelletizer

- Model: SXZGZ-1870

- Power: 15kw

- Diameter: 1800

- Installation Angel: 2°-5°

- Rotary Speed: 11.5(r/min)

- Capacity: 5-8 t/h

How does a rotary drum granulator work?

Production process of npk fertilizer using rotary barrel is complicated, yet Shunxin technique team make our machine operations simple. The compound fertilizer rotary drum granulation can take place because of the combined works of centrifugal force, gravity, frictions between the materials and chemical reactions. The rotary drum compound fertilizer granulator employs wet aggregating granulation to work. By adding a certain amount of steam or vapor, the materials in the tube will then get wet evenly. After sufficient chemistry fully taking place, the rotary drum granulator machine will start to revolve. With the rotary act, the particles of the wet materials will squeeze each other, eventually granulate into fertilizer pellets.

rotary pellet drum

- Model: SXZGZ-2080

- Power: 18.5kw

- Diameter: 2000

- Installation Angel: 2°-5°

- Rotary Speed: 11(r/min)

- Capacity: 8-15 t/h

How to use a rotary drum granulator for making your own fertilizer pellets?

A better understanding of tiltable rotary drum granulator will help you to improve your operations, so we list the operating procedures of it below.

- You must first prepare the raw materials. Whatever they are, cassava, sawdust or poultry manures. You can use Shunxin compost making machine to do the work. After that, put the materials into the big tube. Then add steam or vapor to achieve certain humidity.

- After a little wait for the chemical reactions fully functioning, you can then start the machine to rotate.

- Watch for the diminishment of the materials as the pellets out, and replenish them in time to keep the production process going.

If you have any questions about the granulation process, please contact us for answers. Or you can check the rotary drum granulator instruction manual after purchase.

tiltable rotary drum granulator

- Model: SXZGZ-3210

- Power: 37kw

- Diameter: 3200

- Installation Angel: 2°-5°

- Rotary Speed: 9.5(r/min)

- Capacity: 15-30 t/h

Why Shunxin rotary drum granulators design is reliable?

The Shunxin drum type rotary granulator is constituted by several strictly manufactured parts. The components parts name list and their specialties are as the followings.

- The big tube. The tube is made of medium-carbon steel, the lining inside the tube is made of special rubber or stainless-steel, so the whole tube is durable, corrosion-proof, friction-protective and adhesion-free, provide it with prolonged service life and easy maintenance.

- The toothed-rims and gears. The gears are attached to the toothed-rims, and the big toothed-rims are fixed around the big tube. They make the tube to rotate and work, so they are made of materials that highly wear-resistant. The whole desgin is steady when functioning, so the granulation process can go smoothly and steadily.

- The motor and the decelerator. As the dimensions of these parts in the table below, they are of high quality and durability. We use the wear-resistant materials to build them up, so they can serve you long and well.

- The transmission belt. The belts connect nearly all the parts of the machine, they are important to support the big tube, so the materials of them are very flexible.

- The bracket. Finally the main supporter of the whole machine. Because the bracket must withstand the huge strength caused by high friction of the rotating parts, so it is made to be high wear-resistant and corrosion-protective. They can stand still while the tube is rotating in high speed, so the granulation will take place without any hindrance.

Large scale drum granulation machine

- Model: SXZGZ-3210

- Power: 37kw

- Diameter: 3200

- Installation Angel: 2°-5°

- Rotary Speed: 9.5(r/min)

- Capacity: 15-30 t/h

How much is Shunxin rotating granulator price?

When it comes to price, it is understandable that all the investors want to know. Generally speaking, Shunxin rotating granulator has a reasonable price. It not only has large capacity, but also has wide application. Firstly, you can use our drum pelletizer finish 15-30 t/h granular fertilizer production. Furthermore, it is perfectly for pelletizing both organic fertilizer and compound fertilizer. That is to say, you invest one machine, which can help you to make two types fertilizer.

The most important is Shunxin has its own factory and the rotary drum granulator is manufactured by itself. Therefore, the quotation you get is absolutely factory price. If you have interest, please feel free to inquiry us for the latest information.

The dimensions of Shunxin rotary drum granulators

Here are all the measurements about Shunxin rotating drum granulators for now, since the experts of our technical team are continuously improving our products to perfection, those numbers maybe changed as you checking them. Please contact us for more updates. And if you don’t know which model fit your plant scale better, you are welcomed to consult us.

|

Model |

Power(kw) |

Internal Diameter (mm) |

Length(mm) |

Installation Angle |

Rotate Speed(r/min) |

Capacity(t/h) |

|

SXZGZ-1240 |

5.5 | 1200 | 4000 | 2°-5° | 17 |

1 – 3 |

|

SXZGZ-1540 |

7.5 | 1500 | 4000 | 2°-5° | 14 |

3 – 5 |

|

SXZGZ-1560 |

11 | 1500 | 6000 | 2°-5° | 11.5 |

5 – 7 |

|

SXZGZ-1870 |

15 | 1800 | 7000 | 2°-5° | 11.5 |

7 – 9 |

|

SXZGZ-2080 |

18.5 | 2000 | 8000 | 2°-5° | 11 |

8 – 12 |

|

SXZGZ-3210 |

37 | 3200 | 10000 | 2°-5° | 9.5 |

15 – 30 |